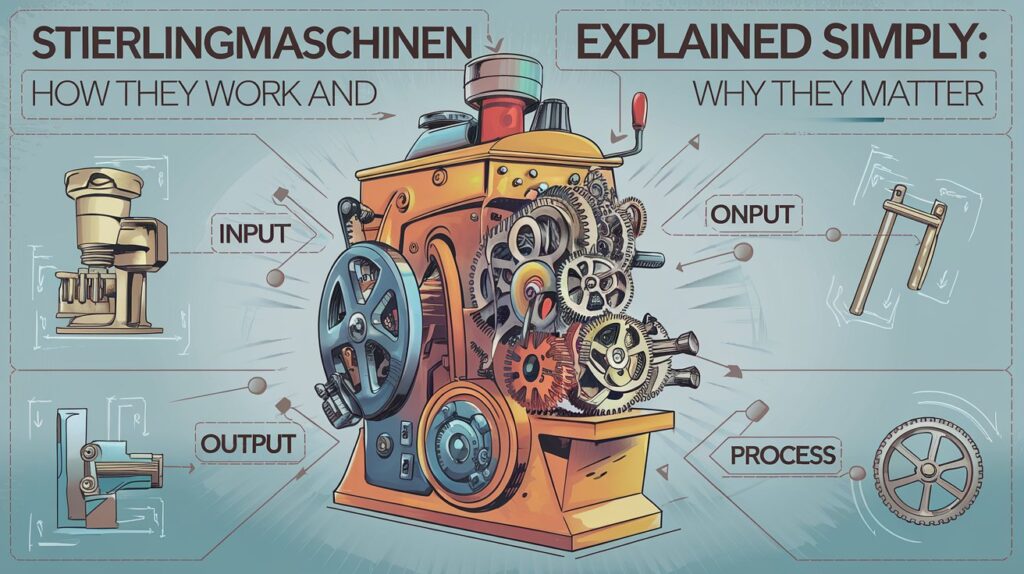

Stierlingmaschinen—also known as Stirling engines—are external combustion engines that use heat to generate motion. Instead of igniting fuel inside the engine like traditional combustion engines, they work by heating and cooling a gas (usually air or helium) in a sealed system.

How Do Stierlingmaschinen Work?

These machines use a temperature difference between two chambers to move pistons. One side is heated, the other cooled. The gas expands when heated and contracts when cooled, pushing the pistons back and forth.

Curious how that creates motion?

The pistons are connected to a crankshaft, converting linear motion into rotary motion—just like a bicycle pedal system.

Why Are Stierlingmaschinen Special?

- They run silently because there are no explosions.

- Low maintenance due to fewer moving parts.

- Fuel flexibility – can run on solar heat, wood, gas, or waste heat.

- Environmentally friendly – zero emissions if powered by clean heat.

Why aren’t they used in cars if they’re so efficient?

They’re great for consistent, low-speed power but respond slowly to quick power demands, making them less ideal for vehicles.

Where Are Stierlingmaschinen Used Today?

- Solar-powered generators in remote locations

- Submarine engines (like in Swedish Navy vessels)

- Waste heat recovery systems in industries

Can I use a Stierlingmaschine at home?

Yes, small hobby kits and solar-powered fans are available. They’re excellent for science projects or low-energy applications.

Real-Life Example: Stirling Solar Dish

NASA and other agencies have tested solar Stirling systems to convert sunlight into electricity efficiently. In sunny areas, these systems can outperform traditional solar panels.

Why isn’t this more common?

Cost and complexity remain challenges, but innovation continues.

Summary: Why You Should Care About Stierlingmaschinen

- Clean energy potential

- Long-lasting and low-maintenance

- Great for off-grid and industrial use

They’re not new, but their timeless design makes them incredibly relevant for a sustainable future.

Comments 2